No matter what you’re working on, how you prototype your idea will make the difference between a final product that’s outstanding or just mediocre. There’s no point putting hours into producing a fantastic product to let it down with some subpar prototype.

Every hour spent on making a quality prototype probably saves you days of trouble down the road when in production.

Here are 5 keys to help you build a better product prototype.

Keep Your Work Organized

Staying organized is a big part for achieving a good prototype. Keeping a log of your product changes and improvements readable will stand you in good stead when working with others. Also, helps you in saving every happy accident that occurs or new technique you discover into a well-documented folder will improve your overall product prototyping arsenal.

Also Read: 7 Strategies You Should Use to Increase Productivity

Making sure you have a process that performs tasks in the right order is also important, as it will help you to keep your eye on the bigger picture rather than getting bogged down in the details, and can also give you the flexibility of delaying certain decisions until the latest possible point.

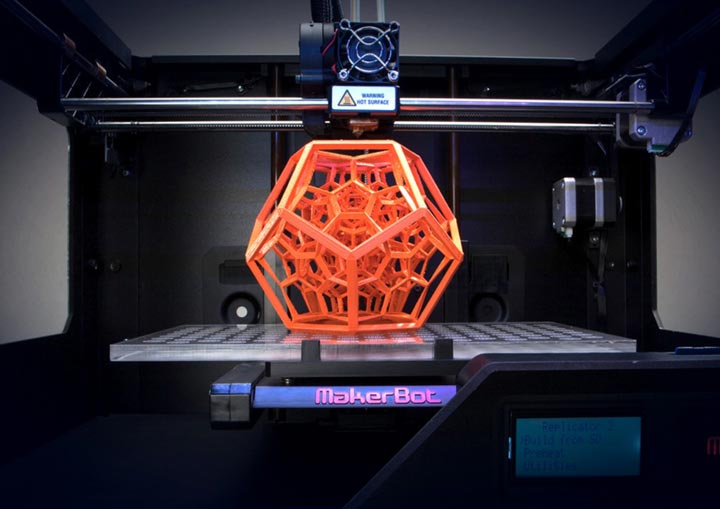

Make Friends with Technology

Since the recent rise in popularity in 3D printing and prototyping, use it to your advantage. So, Learn how to use 3D printers for your business. 3D printing excels at creating custom designs at low cost. It also helps you make quick adjustments and adapt to a faster workflow saving valuable time. Using designing software’s like SolidWorks and simulating software’s like MATLAB and Simulink from Mathworks enables you to preview the functioning of the product prototype in real time accelerating innovation.

Think Through the Wear and Tear

This is where you have to think about how your prototype will move, which part is going to touch and wear off, and what parts are prone to damage. Just because it’s a prototype, this doesn’t mean that you can build something that is not long lasting and durable. The same thing applies to damage; if your product prototype is going to be moved around for product launch and demos, it is most likely going to be worn, scratched and damaged. So, always have tools and extra spares ready for replacement.

Choose your Materials Wisely

I really can’t stress the importance of this enough. A faulty material setup can ruin an otherwise good

prototype completely. Bending the rules, a little at times for design reasons or due to limitations is fine, but that should always be a conscious choice rather than something that just happens as a result of ignorance. Therefore, choose materials wisely that suits your product prototype.

Don’t Forget the Product Prototype Design

Not focusing entirely on design may be great and speeds up your work by a lot. But, in the end it’s the design appeal and craftsmanship that will sell a product to the customer. Many investors shy away from investing in a product, where a prototype has poor or no design. Spend some time adding those final touches of design for visual appeal. Remember, a product prototype is equal parts engineering and design.